|

|

TODAY.AZ / Weird / Interesting

How Roboticists can tackle climate change

04 March 2023 [22:21] - TODAY.AZ

The world emits 51 billion tonnes of greenhouse gases into the atmosphere every year. To solve the climate crisis, we need to cut this in half by 2030, and get to zero by 2050. For electricity generation, this means the United States alone needs to increase renewable-energy capacities by 10 times over the next 12 years, which roughly translates to a mind-boggling 400,000 more wind turbines and 2.5 billion more solar panels. To accelerate this progress, Congress has recently passed the Inflation Reduction Act, which includes billions of dollars for clean-energy projects. We will need a lot of workforce to install and maintain these facilities at the front lines, which are not always well suited to humans.

As a roboticist, I see these dull, dirty, and even dangerous tasks as the perfect area for robots. However, there’s a shortage of roboticists tackling climate change, due to a lack of awareness of necessary and urgent applications. After talking with many climate robotics founders for my blog, Nirva Labs, here are my findings on how you can find opportunities to help robots make an impact on climate change.

The first robot I built from scratch was SS MAPR, an autonomous boat for water departments to collect multidepth water-quality data. They use this data to monitor river pollution and rein in pollution sources. To this day, it remains the most exciting project I’ve ever worked on. After six months of 80-hour weeks and sleepless nights, SS MAPR was able to finish its maiden voyage with water samples and data collected from the bottom of the Schuylkill River, in Pennsylvania. That was the eureka moment for me: All the prototyping and coding resulted in faster and cheaper access to the data that drives regulatory actions. I want to build more robots that improve the environment we live in.

Stunned by the rampant wildfires after moving to the Bay Area in 2020, I started Nirva Labs to write about climate robotics opportunities. Surprisingly, many founders I talked with echoed the shortage of roboticists in climate tech. This was disproportionate to the huge potential of robotics for solving climate problems. My personal experience confirmed those observations. At all the robotics events I went to in the Bay Area, one of the biggest robotics hubs in the world, I could barely find anyone working on climate. The investment data backed this up—according to PitchBook, climate robotics accounts for less than 1 percent of total robotics venture funding over the past five years.

Why aren’t there more roboticists working on climate change? After talking to some peers, I realized that from a superficial perspective, climate change doesn’t seem to need robotic inventions—we already have most of the solutions in nonrobotic forms. But that’s exactly why climate change needs robotics to do the repetitive work: to scale up existing solutions so we can get to net zero in time.

Using robots to scale up existing climate solutions

To understand why robotics is crucial for tackling climate change, we should look to an analogous case: the automotive industry. For a long time, cars were made by humans. In 1925, assembling one Ford Model T required an average assembly speed of 3.76 seconds per part. This was the norm for almost 40 years, before General Motors introduced a robotic arm to assist in the assembly line. Today, assembling a Toyota SUV takes about 2.04 seconds per part, an 84 percent improvement from a century ago—even though the assembly process has exploded in complexity.

This is the sweet spot for robotics—freeing humans from repetitive tasks while increasing efficiency. Climate tech is in a state similar to that of the early automotive industry. Most building blocks of the overall climate solution already exist (for example, solar- and wind-energy generators, electric vehicles, heat pumps) but need to be deployed at scale quickly in order to go from 51 billion tonnes of greenhouse gas emissions to net zero by 2050. By doing what they do best, robots can play a big role in accelerating the fight against climate change by enabling economies of scale.

Finding climate robotics opportunities

There are many technically feasible opportunities in climate robotics that can have an impact on the climate, but how do you actually find one? The best way is to deeply learn and understand the life cycle of an existing climate solution and identify how automation can accelerate it. But for any climate solution, it’s important to watch out for its overall climate impact: is it directly mitigating or removing greenhouse gas emissions, helping us adapt to the impacts of climate change, or enhancing our understanding of the climate? The overall impact involves not only the technical solution but also the economic and political forces around it. So it’s important to trace the solution down the entire life cycle and get a full picture of the pros and cons.

Climate robotics opportunities for renewable energy

The renewable-energy sector is a great place to search for climate robotics opportunities. Energy sources like solar and wind are already cost competitive compared with fossil fuel. Robots can help eliminate the bottlenecks that limit their expansion.

Starting from the source of the renewable-energy value chain, robots can help remove the labor bottleneck for installing solar and wind farms. For example, one of the most time-consuming and dangerous tasks in building solar farms is heavy lifting. AES, an energy giant, has developed an automated solar farm construction robot to solve this problem. The robot can automatically install solar panels on pre-installed foundations to free workers from lifting. It is also three times as fast as a human, and the new solar layout can generate twice as much solar energy within the same footprint. This is a great example of how outdoor autonomous navigation and robot manipulator control speeds up the renewable-energy transition.

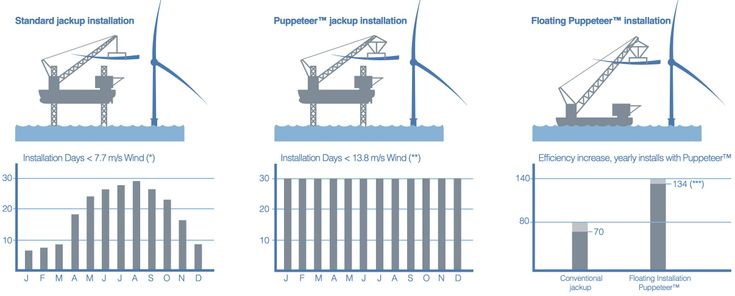

Offshore wind-farm construction faces a different challenge, with installations limited from April to November because the high wind conditions in the winter make it challenging for high-precision tasks such as blade installation. X Laboratory, a Dutch company, has developed a motion-compensation technology to keep a crane stable during the blade-installation process, which can increase the wind-speed tolerance and thus increase the installation days to all year round. The team is currently improving the technology to compensate for disturbances from waves, so installation can be done on floating vessels instead of jack-up vessels, which stand on the seabed. This could potentially double the construction speed. This is a creative and effective climate application of robust robot control.

Renewable-energy facilities need routine maintenance to stay efficient. With their rapid expansion over the past decade, there has been a shortage of skilled maintenance technicians. For example, inspecting and repairing onshore wind turbines involves hanging a person 150 meters above the ground, which can be done only by well-trained rope-access technicians. Many wind-farm operators have to hire technicians from out of state at a high cost, which pushes up the overall cost of wind energy.

Many companies have been using automation to solve this problem. Companies like Unleash are using drones to speed up blade inspection, while Aerones has developed a tethered drone supported by a rope system that has a bigger payload and better stability. This expands the task envelope from inspection to cleaning, coating, and simple repairs. Sometimes a creative spin on an existing robot brings a big impact.

And there are many more robotics opportunities throughout the renewables value chain. Batteries are an important buffer for renewable energy, which varies throughout the day. However, there is a shortage of critical battery minerals like lithium and cobalt. Companies like Impossible Metals are working on robots to harvest ore nodules from the seabed to alleviate this shortage. On the other end of the battery life cycle, both academia (Oak Ridge National Laboratory) and industry (Posh Robotics) have been developing robots to repurpose retired EV batteries, which still have 80 percent storage capacity at the end of their lives and can be used as energy storage for buildings. Robotics speeds up the process and reduces human exposure to toxic chemicals and high voltage levels.

URL: http://www.today.az/news/interesting/232378.html

Print version

Print version

Connect with us. Get latest news and updates.

See Also

- 25 January 2026 [22:33]

Scientists solve 66 million-year-old mystery of how Earth’s greenhouse age ended - 20 January 2026 [14:34]

Spain train crash death toll rises to 41 after high-speed derailments - 19 February 2025 [22:20]

Visa and Mastercard can return to Russia, but with restrictions - 05 February 2025 [19:41]

Japan plans to negotiate with Trump to increase LNG imports from United States - 23 January 2025 [23:20]

Dubai once again named cleanest city in the world - 06 December 2024 [22:20]

Are scented candles harmful to health? - 23 November 2024 [14:11]

Magnitude 4.5 earthquake hits Azerbaijan's Lachin - 20 November 2024 [23:30]

Launch vehicle with prototype of Starship made its sixth test flight - 27 October 2024 [09:00]

Fuel prices expected to rise in Sweden - 24 October 2024 [19:14]

Turkiye strikes terror targets in Iraq and Syria

Most Popular

Partial U.S. government shutdown enters new phase amid budget dispute

Partial U.S. government shutdown enters new phase amid budget dispute

Apple acquires AI startup that reads facial movements

Apple acquires AI startup that reads facial movements

Azerbaijan’s Azeri Light oil prices increase in global markets

Azerbaijan’s Azeri Light oil prices increase in global markets

Kyiv metro temporarily closes due to power shortage

Kyiv metro temporarily closes due to power shortage

Britain’s Starmer ends China trip aimed at reset despite Trump warning

Britain’s Starmer ends China trip aimed at reset despite Trump warning

Pakistan says 48 killed in coordinated attacks in Balochistan

Pakistan says 48 killed in coordinated attacks in Balochistan

Writer’s House hosts inaugural ‘Yüks?li?’ series on Azerbaijani language and ideology

Writer’s House hosts inaugural ‘Yüks?li?’ series on Azerbaijani language and ideology