|

|

TODAY.AZ / World news

Chinese scientists create 3D printer that prints ready-made food

01 April 2025 [19:21] - TODAY.AZ

By Alimat Aliyeva

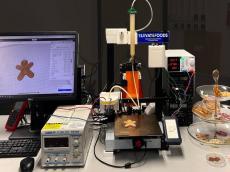

Chinese scientists from the Hong Kong University of Science and Technology (HKUST) have developed an innovative 3D food printing system that combines artificial intelligence (AI) with infrared cooking technology, Azernews reports.

The new system addresses key challenges faced by traditional 3D food printing, such as the need for additional post-processing, the risk of microbial contamination, and the limited complexity of molds.

By using graphene heaters and precise temperature control, researchers have developed a method to print complex starch-based foods that are cooked simultaneously during the printing process, while maintaining perfect shape and quality.

A unique feature of the development is the integration of generative AI, which utilizes special algorithms to create intricate food patterns, offering more design flexibility and customization in food preparation.

This technology holds significant potential for personalized nutrition, particularly for individuals with specific dietary needs, such as those suffering from dysphagia (swallowing disorders). It could be used in nursing homes, hospitals, and restaurants, providing new opportunities for culinary innovation and expanding the range of foods available to people with special dietary requirements.

In the near future, scientists plan to further optimize the technology to preserve heat-sensitive vitamins and improve the digestibility of starches. Additionally, studies are underway to assess how various consumer groups perceive this technology, which will be a crucial step toward its commercialization.

The introduction of this technology could revolutionize the way we think about food production, especially in environments like hospitals where specialized meals are crucial. The ability to create custom food designs and textures tailored to individual dietary needs could significantly improve the quality of life for those with medical conditions that affect their ability to eat. Furthermore, this technology opens the door to more sustainable food production methods, potentially reducing food waste by printing only the necessary quantities of food.

URL: http://www.today.az/news/regions/258083.html

Print version

Print version

Connect with us. Get latest news and updates.

See Also

- 01 November 2025 [19:19]

Serbians mark anniversary of deadly station collapse with mass protests - 01 November 2025 [10:31]

Seismic activity persists in Türkiye - 01 November 2025 [09:00]

YouTube TV no longer carry Disney content after deal talks collapse - 01 November 2025 [08:00]

LG partners with Nvidia on physical AI and digital twins - 31 October 2025 [23:25]

Tesla recalls Cybertruck electric trucks from customers - 31 October 2025 [22:46]

Cars most frequently sold by owners within year revealed - 31 October 2025 [22:23]

US mulls ban on popular Wi-Fi routers - 31 October 2025 [21:50]

Character.ai limits AI chat access for underage users - 31 October 2025 [19:52]

Pakistan agrees to continue conditional ceasefire with Afghanistan - 31 October 2025 [19:23]

France launches world's first EV-charging motorway

Most Popular

Art Weekend presents exhibition 'In Dew. The Morning That Never Was'

Art Weekend presents exhibition 'In Dew. The Morning That Never Was'

Pashinyan vs. Etchmiadzin: who is who?

Pashinyan vs. Etchmiadzin: who is who?

Leyla Aliyeva attends presentation of 'Hirkan' documentary

Leyla Aliyeva attends presentation of 'Hirkan' documentary

Baku hosts international conference on Belgium’s colonial past and its lasting impact

Baku hosts international conference on Belgium’s colonial past and its lasting impact

Pashinyan calls for public backing of peace with Azerbaijan, says ‘historic change’ achieved

Pashinyan calls for public backing of peace with Azerbaijan, says ‘historic change’ achieved

Honda reportedly pauses production in Mexico due to chip shortage

Honda reportedly pauses production in Mexico due to chip shortage

World's first "sky stadium" to be built in Saudi Arabia

World's first "sky stadium" to be built in Saudi Arabia